What is an OH&S Risk Analysis?

What is an OH&S Risk Analysis?

One of the most important steps in your Occupational Health and Safety Management System (OHSMS) implementation project is to perform the risk analysis of health and safety hazards that may be present in your workplace(s).

One of the key benefits of ISO 45001 is that it uses a simple plan-do-check-act (PDCA) model. This model allows organizations to plan what the need to do in order to minimize risk of harm. When defining what these risks are, measures taken must address concerns that may lead to long-term health issues, absence fromwork as well as possible accidents.

IS0 45001:2018 emphasizes risk, weaving risk throughout the standard. The new ISO 45001:2018 standard expects organizations to identify workplace hazards and address risks associated with their operations, processes, and activities, aimed at, and resulting in improved OH&S performance. Not only are organizations expected to identify the risks, the new ISO standard expects organizations to address opportunities for improvements, and take corrective actons based on risk.

Risk is seen in many areas of the 45001:2018 standard. Risk is addressed throughout the requirements in clauses 5,6,7,8,9 and 10 with the requirement outlined clearly in clause 6.

It is important to understand what the Risk Analysis involves, and what information it will provide. Typically, the risk analysis process starts with the preparation of process flow diagrams to describe the activities/steps. It follows with the initial reviews and the completion of checklists to identify hazards that may be present in your workplaces. It continues with the use of an 8-column risk management worksheet that takes you through a series of information gathering actions designed to assist in deciding whether or not a hazard and/or process step is at risk and concludes with taking appropriate corrective actions.

The most important tool for this initiative is the worksheet for OH&S Risk Analysis is the Hazard Identification, Risk Assessment and Determining Controls. The 8-column worksheet is used to cover the office/administrative and the plant/manufacturing workplaces. The Worksheets provide the implementation team with a report of the findings and tell them what areas of your workplaces need corrections. The team will now know how to manage the health and safety risks.

Scheduling and Conducting the OH&S Risk Analysis

Review the project plan: Who did you identify to conduct the analyses?

Schedule time to analyze the risks for the office and plant workplaces.

Conducting the Analyses

Use the 8-column worksheet to cover both the office/administrative and the plant/manufacturing workplaces.

- Column 1 — Transfer from the initial review checklists, the items that need attention.

- Column 2 — Identify what may be present or could be introduced as a risk.

- Column 3 — Describe the risks that may exist or could be introduced.

- Column 4 — Assess the significance of the described risk. A general approach is:

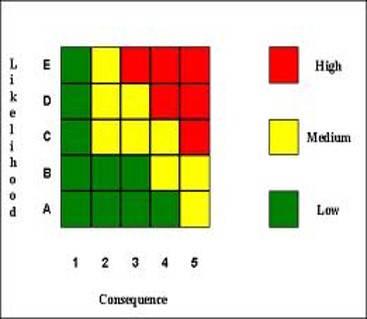

- Indicate the severity as L for low, M for medium, H for high.

- Indicate the likelihood of occurrence as Low, Medium or High.

- When both the severity and likelihood are high, the significance is high, the hazard presents a risk, it requires attention and corrective action is required.

- When one or both severity and likelihood are indicated as medium, additional reviews are required and resulting actions justified with inputs in columns 5 & 6

- Column 5 — For Low, Medium, and High significance risks indicate if the risk can be eliminated or reduced in a next step in the process.

- Column 6 — For all risks, describe what controls are in place to reduce or eliminate the risk.

- Column 7 — The Team considers the inputs from columns 1 through 6 and indicates with a NO or a YES whether or not the hazard/item/process step is a risk.

- Column 8 — With a NO decision, a corrective action request (CAR) is not needed and N/A is indicated in this column.

With a YES conclusion, the team leader, enters CAR # in the last column and prepares and issues a Corrective Action Request to the individual responsible for the process step.

With the determination, implementation, and monitoring of controls needed to mitigate the effects of the hazards and their risks; the risk management loop is completed with improvements in health and safety performance which results in workplaces that are safer and healthier.

Reporting

The completed Hazard Identification, Risk Assessment and Determining of Controls worksheets provide a report with the details on how you manage the health and safety risks for your organization.

Purchase our COMPLETE – Risk Analysis Guide – (see below)

Benefits of the Risk Analysis Package:

The Risk Analysis Package addresses the ISO 45001requirements of clause 6.1.2, Hazard identification and Assessment of OH&S risks, the overall risk management initiative. It provides the tools for every step of your risk program:

- Audit Checklists to complete the initial OH&S reviews for both your office and plant workplaces.

- Procedures to document your Risk Management System

- Worksheets to identify hazards, assess the risks associated with them and determine the controls needed to improve your OH&S performance.

- Improve risk management with a follow Up Worksheet and CAPA Guide

These tools provide a practical approach to risk management that can be applied to all types of workplaces where health and safety risks can vary and be very different depending on the nature of the business and products/services in a wide range of industries. For example:

- An administrative setting (consulting firm) can reveal conclusions with simple solutions

- A complex industrial setting (manufacturing processes) can yield more technical conclusions and solutions.

The package is a cost-effective approach to begin the process. The risk analysis exercise follows a simple series of steps:

-

- Start with the preparation of process flow diagrams to describe the activities/steps.

- Perform initial reviews to identify hazards that may be present in your workplaces.

- Use risk management worksheet to decide whether or not a hazard and/or process step is at risk

- Take appropriate corrective actions.

As you proceed with your OH&S project, the 31-page guide includes everything you’ll need to complete the assessments of risks and manage the health and safety risks for your organization.

Contents

Risk Management Tools Package includes:

- Risk Analysis Guide (31 pages)

- Instructions

- Process Flow Modeling

- Initial Review Checklist – for the office workplace

- Initial Review Checklist – for the plant workplace

- Improvement Action Follow-Up worksheet

- 8 Column Risk Analysis worksheet

- Instructions covering the office and plant workplaces

- Procedure P-612, OH&S-Risk management planning covering:

- Initial Review and

- Hazard Identification, Risk Assessment, and Control

- Corrective-Preventive Action Planning Guide

Compare Products

| Risk Management Tools | Gap Checklist | |||

| Initial Review Checklist – Office Workplace | ||||

| Initial Review Checklist – Plant Workplace | ||||

| OHS Program Action Plan | ||||

| Risk Opportunity Worksheet | ||||

| Risk PowerPoint | ||||

| Gap Analysis Checklist | ||||

| Support | ||||

| $39.00 Order Now |

$49.00 Order Now |

|||